Our capabilities include:

- Die Cutting

- Compression Molding

- Slitting

- In House Mold Production

- Water Jet Cutting

- Transfer Molding

- High Precision Cutting

- Bonding/Vulcanizing

- Liquid Injection Molding

- Extruding

Our equipment includes:

- (6) Freeman Schwabe C-Frame Die Cutting Presses

- Haas VF3YT CNC Mill

- Aerodyne Compression Molding Vacuum Press

- Various Transfer Molding Presses

- Lever Slitter

- Various Custom Preform Extruders

- Computer Controlled Mixers

- Various Manual Lathes and other general tools

- Flow IFB 6’x12′ 4 Head Water Jet

- Amada Fabrivision Laser Inspection Machine

- Various Compression Molding Presses

- Boy 55E Injection Molding Press (LIM)

- 3.5″ Diameter Hot Feed Extruder

- Various Ovens

- Instron Material Tester 3345

- Various Quality Department Tools

Our knowledgeable staff backs up our extensive capabilities with specialized expertise in almost all fields of gasketing. For flat gaskets we are able to cut and produce continuous unbonded gaskets up to 6′ wide x 12′ long. For molded gaskets we can make anything unbonded up to 27″ x 27″. When Bonding or Vulcanizing is an option there are no limitations. We can do all this while maintaining very tight tolerances. We also maintain a specialized expertise in the area of EMI/RFI Shielding Gaskets. Our SAS SEALTRON® Brand which can be found in the EMI/RFI Shielding section of this website are a group of highly conductive elastomers that provide both an environmental seal and EMI/RFI Shielding.

SAS carries a wide variety of Solid Neoprene, Nitrile, and EPDM in both commercial and military specification grades with Durometers ranging from as low as 10A all the way up to 100A. We can supply these

materials in any design you can come up with as a finished part or in roll or sheet stock, of course either format can be done with any PSA/Liner combination you can think of if necessary. Most commercial grade thicknesses and some raw uncured rubber is kept in stock allowing us to meet even the strictest of timelines. We also have many fabric inserted variants should you require them. Along with our solid Neoprene, Nitrile, and EPDM materials we also carry a wide range of Closed Cell Foams, which is also in both commercial and military grades using various different types of Neoprene/Nitrile/EPDM blends to meet military standards at a significant cost reduction along with 100% Neoprene Base options.

Neoprene Gaskets & Materials

Advantages:

Very high resistance to O-Zone, Oil, and many common chemicals.

Disadvantages:

Susceptible to esters, oxidizing acids, ketones, chlorinated, aromatic and nitro hydrocarbons.

Examples:

Garden Hoses, Plumbing Fixtures, Water Resistant Covers & Boxes

Nitrile (Buna-N, NBR) Gaskets & Materials

Advantages:

Good resilience, tensile, and compression set. Very resistant to both mineral and vegetable oils.

Disadvantages:

Susceptible to ozone, ketones, esters, aldehydes, chlorinated and nitro hydrocarbons.

Examples:

Oil Wells, Automotive Hoses, O-Rings

EPDM Gaskets & Materials

Advantages:

Great for outdoor environments. Offers excellent resistance to both ozone, oxidants, and severe weather conditions.

Disadvantages:

Bad electrical insulator, very low tensile strength and resilience. Susceptible to mineral oils, solvents, and aromatic hydrocarbons.

Examples:

Weather Stripping, Automotive Painting Booths

As with all of our materials these can be supplied in finished parts to your design, roll or sheet form, slit to width rolls, and extruded profiles all with any configuration of adhesives and/or liners you can think of.

We also carry a wide range of both Solid and Closed Cell Sponge Silicones and Fluorosilicones, commonly used in high temperature applications, meeting commercial grades and many military specifications. us to provide you with both the rarest and highest quality silicones that many companies would have a hard time finding from our own stock enabling us to give you the rapid delivery you require. As with our other rubbers we can cut or mold almost any part you can design or provide us with a sample on.

Silicone Gaskets & Materials

Advantages:

Excellent Thermal Stability (consistent performance over -100 to +250 °C), Repels Water to form a Water Tight Seal, Excellent Resistance to Oxygen, Ozone, and Sunlight, Good Electrical Insulation, Low ChemicalReactivity, Low Toxicity, High Gas Permeability.

Disadvantages:

High Relative Cost to other common rubbers such as Neoprene/EPDM/Nitrile

Examples:

Cookware (heat insulating), Electronic Components, Firestops

Fluorosilicone Gaskets & Materials

Advantages:

All The Advantages of Silicone, Added Resistance to Certain Jet Fuels

Disadvantages:

Higher Relative Cost Than Silicone

Examples:

Fuel Bladder Covers, Aerospace Applications

As with all of our materials these can be supplied in finished parts to your design, roll or sheet form, slit to width rolls, and extruded profiles all with any configuration of adhesives and/or liners you can think of. Of course we specialize in conductive silicone formats which can be found in our

EMI Shielding section.

An excellent choice when your application requires the strictest of chemical resistances and high temperature sustainability. Please contact us with your requirements and we will tell you if Viton™ is a good fit. We stock a wide range of Viton™ Polymers and sheet thicknesses to many different military and commercial specifications. We can both mold and cut from this material. We also have many cloth inserted variants should your application require one.

Viton™ Gaskets & Materials

Advantages:

Sustained Performance in Aggressive Chemical Environements

Disadvantages:

High Relative Cost to base rubbers such as Neoprene/EPDM/Nitrile

Examples:

Oil Exploration, Chemical Process Plants, Oxygenated Automotive Fuels, Aerospace Fuels & Lubricants

As with all of our materials these can be supplied in finished parts to your design, roll or sheet form, slit to width rolls, and extruded profiles all with any

configuration of adhesives and/or liners you can think of.

Frequently, your applications may require a need for an above average sized gasket that you may be having a hard time finding someone to manufacture. We pride ourselves on our ability to manufacture to any size using our knowledge and experience. Our customers, frequently, come to us for oversized gaskets in any shapes and sizes, most typically in the oversized area, large “washer style” gaskets or ID/OD Rectangles typically referred to as “window frame” gaskets. Whether you deem your design large, very large, or even “too large” we will gladly manufacture it for you.

When necessary we have the unique capabilities of holding to even the tightest of tolerances, within a micrometer. When your gasket designs must be perfect please contact us and we will manufacture with that in mind. These special gaskets are typically used by aerospace manufacturers where the gaskets must be true to design and there is no room for error. Keep in mind when requesting this option tooling will be substantially more expensive.

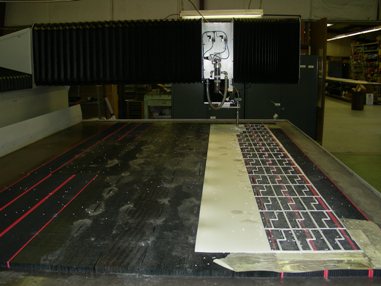

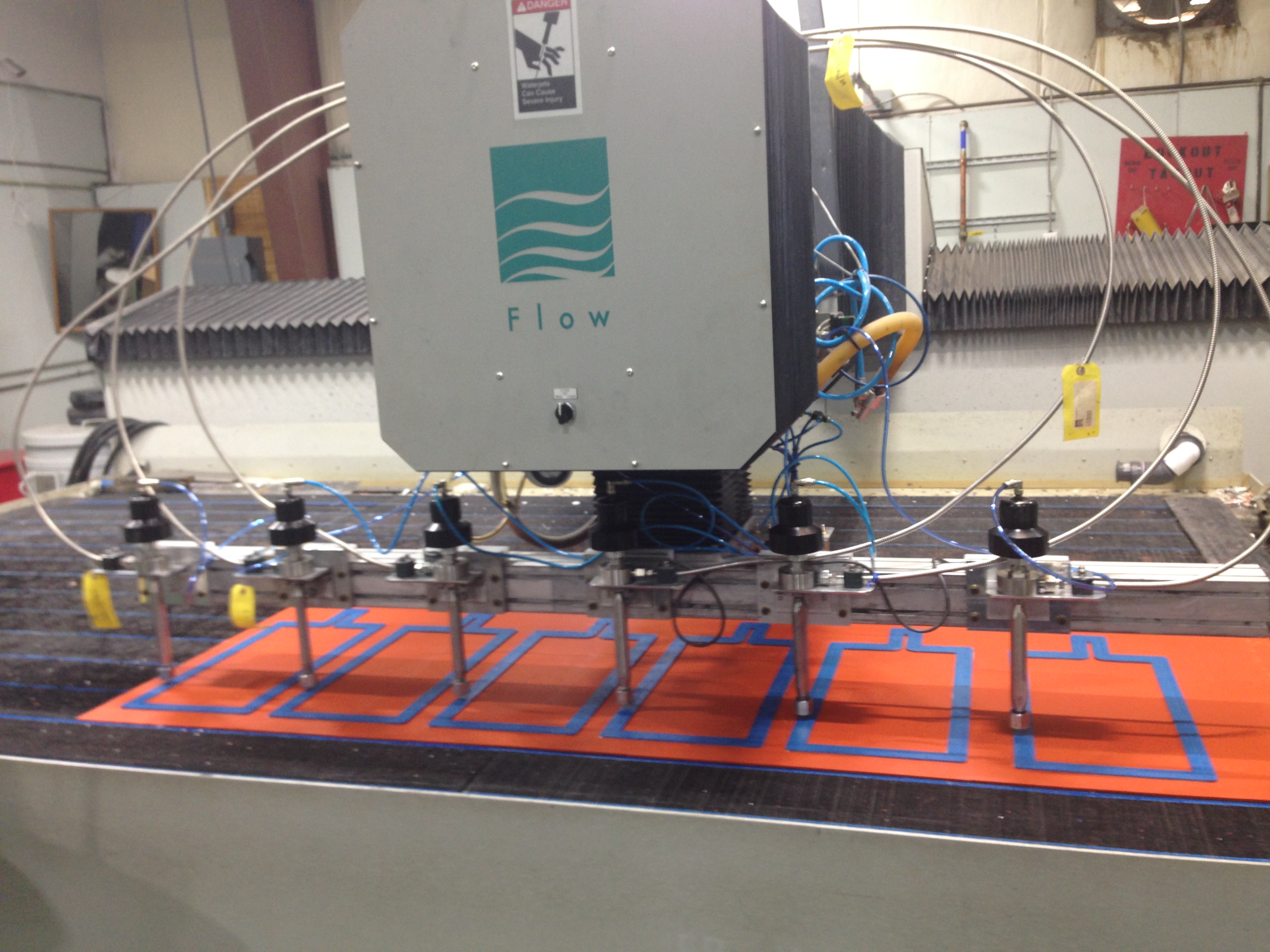

Our Water Jet Machines can cut everything from common rubbers and plastics to the hardest of steels including 4″ titanium. The advantages of Water Jet cut parts are that they involve no tooling which allows for quick deliveries and no tooling charges. They also enable extremely precise parts to your specifications. Our water jet machines (one such is pictured above) hold industry leading tolerances of +/- .003″ with repeatability to +/- .002″. The particular machine pictured above also represents one of the largest cutting surfaces available (6 ft x 12 ft). This enables us to provide seemless parts with no bonded joints in any size that fits within that rectangle area. Other benefits to Water Jet Cut Gaskets are with thick rubbers in both solid and sponges where the typical method of manufacture, die cutting, would cause a severe concavity, water jet cutting provides a seemless wall similar to if the part had been molded, though not quite as smooth. If you are having a hard time with any of your designs or ideas and are not sure if it is best to Die Cut, Mold, or Water Jet cut the part call us and we will decide for you and provide you with exactly what you desire.

Advantages of Water Jet Cutting With SAS:

- 6 Cutting Heads For Cutting Up To 6 Parts Simultaneously

- Large Cutting Area (6′ x 12′)

- Advanced Material Utilization through the use of superior nesting algorithms (ProNest Nesting Software)

- Experience (We have cut over 10,000 unique parts, some hundreds of thousands of times using our Water Jets.)

- Top of the line machinery (We exclusively cut using Flow Water Jet Machines)

SAS fabricates from a wide variety of Plastic and Paper materials. Please contact our friendly sales staff for more information.

SAS fabricates from virtually all Thermally Conductive Materials. We convert from all of Bergquist™, 3M™, Bergquist™, Chomerics™, Laird Technologies™ Thermagon, Saint Gobain™ and Bergquist™ Thermal Pads. We also have access to many other Thermal Pad materials.

Poron™ Microcellular Urethane Foams offer a lot of advantages for customers looking for Open Cell gaskets. Poron™ materials are flexible, high density, microcellular products that offer excellent resistance to compression set, exhibit high resilience, good vibration dampening and impact absorption. Perhaps most importantly Poron™ products are very resilient offering sustained performance after continued use. SAS has the capability to cut any gasket out of any style of Poron™.

SAS also manufactures out of some Open Cell Sponge. Open Cell Sponges are used for their excellent compression set characteristics.

Poron™ Gaskets & Materials

Advantages:

Excellent Compression Set Offering Long Term Performance, Low Outgassing and Non-Fogging, Non-Corrosive to Metal, Excellent Perfomance from -40 to +90 °C, Good Chemical Resistance

Disadvantages:

Poor Fuel Resistance

Examples:

Abrasion Resistance Applications, Enclosing Electrical Components.

Open Cell Sponge Gaskets & Materials

Advantages:

Excellent Compression Set Characteristics

Disadvantages:

Poor Water Resistance

Examples:

Cushions, Mattresses

As with all of our materials these can be supplied in finished parts to your design, roll or sheet form, slit to width rolls, and extruded profiles all with any configuration of adhesives and/or liners you can think of.

SAS carries and manufactures a wide range of conductive silicones and knitted wire mesh material. These products can be molded or cut to your designs as well as being sold in sheet stock. For more information on this material please visit our

EMI Shielding section.- Saint Gobain™ and CHR™ Silicones are trademarks of the Saint-Gobain™ Company.

- Bergquist™ is a trademark of the Bergquist™ Company

- ILaird Technologies™ is a trademark of Laird™ PLC

- Chomerics™ is a trademark of the Parker Hannifin Company

- Viton™ is a trademark of DuPont™ Performance Elastomers LLC.

- Poron™ is a trademark of the Rogers™ Corporation.